Florida's 2023 Building Code Changes: 5 Steps to Streamline Your Duct Leakage Testing (Easy Guide for Energy Auditors)

If you're an energy auditor working in Florida, you've probably already felt the impact of the 2023 Florida Building Code changes. The 8th Edition of the Florida Building Code's Energy Conservation section brought some updated duct leakage testing requirements that are now mandatory for all new construction projects.

The good news? With the right approach and equipment, you can streamline your testing process and knock out these jobs faster than ever!

Let's break down the five essential steps to help you navigate Florida's updated building code while maximizing your efficiency on every job site.

Step 1: Verify Testing Applicability and Equipment Calibration

Before you even load up your truck, make sure you understand when testing is actually required.

According to Section R403.3.3 of the Florida Building Code, duct testing is mandatory for all new construction. But here's the kicker, there's an exception! If the ducts and air handlers are located entirely within the building thermal envelope, you're off the hook.

For projects claiming credit under the R405 Performance Path, duct air leakage verification is required if you're targeting lower than the default Qn rating of 0.080 (that's duct leakage to outside in cfm per 100 square feet of conditioned floor area).

Get Your Gauges Ready!

Now let's talk about your duct leakage test equipment. Whether you're using a DG-1000 or DM-32 manometer with your Minneapolis Duct Blaster or Retrotec system, calibration is everything.

A miscalibrated gauge can throw off your entire test, leading to failed inspections or, even worse, callbacks. Check your equipment before heading out, and make sure your manometer is reading accurately at the required test pressure of 0.1 inch w.g. (25 Pa).

Keep a calibration log. Your future self will thank you when an inspector asks about your equipment accuracy!

Step 2: Seal Those Vents (and Ditch the Tape Hassle!)

Here's where most energy auditors waste precious time on every single job. Traditional methods involve climbing ladders, wrestling with rolls of tape, and dealing with the inevitable sticky mess on registers and walls.

Sound familiar?

Let's talk about a better way: reusable vent caps.

Why Vent Caps Are a Game-Changer for Duct Testing Efficiency

Traditional tape sealing can eat up 30-45 minutes of your day, per house! And if you're running a multi-crew operation? That time adds up fast.

Vent Cap Systems' reusable seals go into place in seconds - from the ground - creating an airtight seal without any adhesive mess. No more pulling paint off registers. No more worried homeowners watching you tape up their brand-new walls. No more ladders for those hard-to-reach ceiling vents!

The best part? These caps work with virtually any standard vent size, and you can reuse them job after job after job. That's efficiency and sustainability rolled into one!

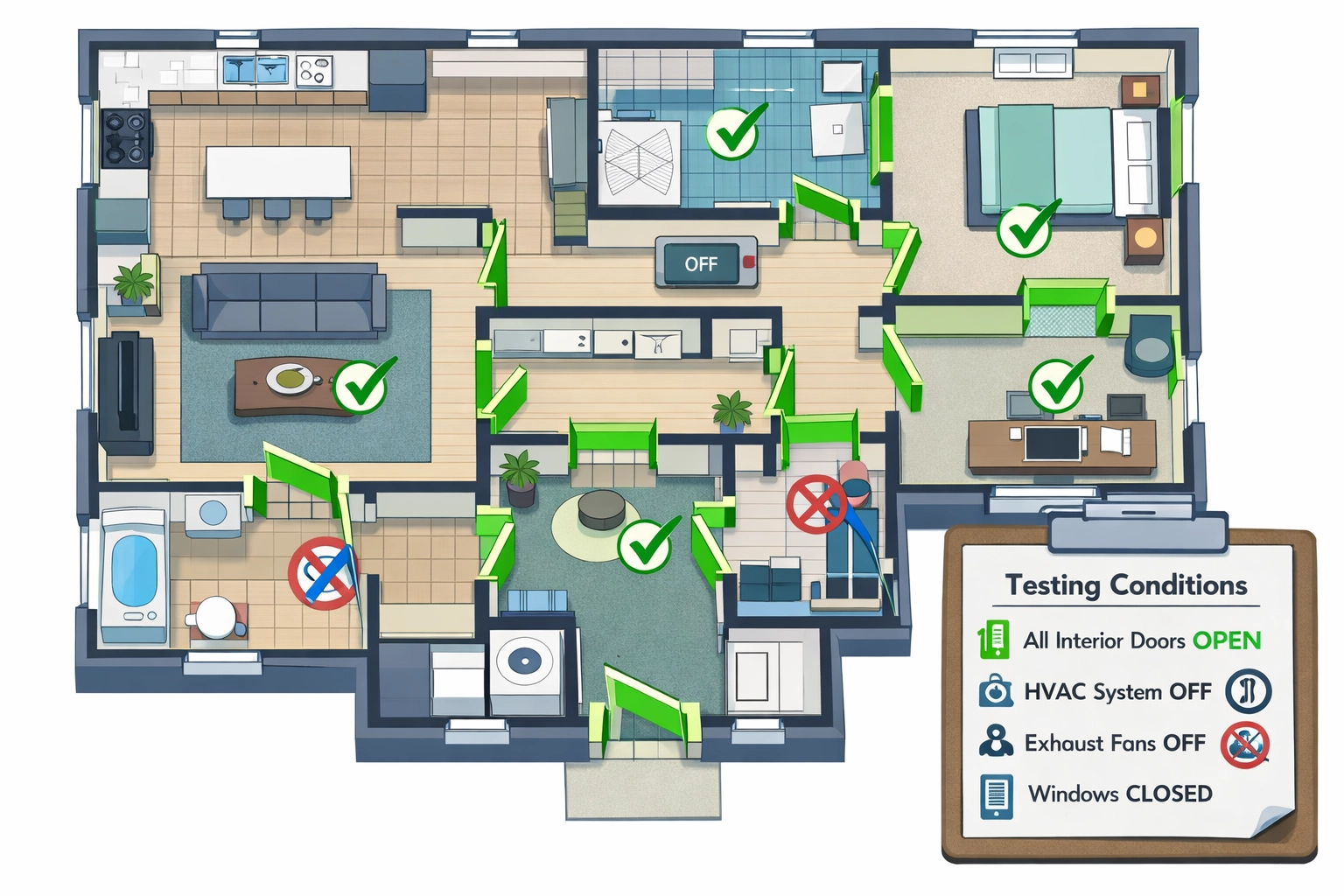

Step 3: Prepare Testing Conditions According to Code

Florida's 2023 code is pretty specific about testing conditions, and getting this right is crucial for accurate results.

Before you fire up that duct blaster, make sure you've checked all these boxes:

- Interior doors: Open 'em all up

- All registers: Sealed tight (this is where your vent caps shine!)

- Exterior doors: For continuous ventilation systems and heat recovery ventilators, these need to be closed and sealed

- Dampers: Close exhaust, intake, makeup air, backdraft, and flue dampers, but don't seal them beyond their intended infiltration control measures

This setup ensures you're testing the duct system in conditions that match real-world performance while meeting the ANSI/RESNET/ICC 380 standards that Florida requires.

Pro tip: Create a quick checklist on your phone or tablet. It takes two minutes but can save you from having to redo an entire test because you missed something!

Step 4: Conduct the Pressure Test at the Right Differential

Now we're getting to the heart of the matter, the actual duct leakage test!

Florida's code requires testing at a pressure differential of 0.1 inch w.g. (25 Pa) across the entire system. This is standard stuff, but it's worth emphasizing because consistency is key.

Two Testing Methods: Rough-In vs. Post-Construction

You've got options here:

Rough-in test: This happens with the manufacturer's air handler enclosure installed (if it's available at the time of testing). Many contractors prefer this route because it allows them to identify and fix leaks before drywall goes up.

Post-construction test: Conducted after final construction is complete, including the air handler enclosure. This is your "final exam" to prove everything's buttoned up tight.

Both methods are valid under Florida's code, but make sure you're following ANSI/RESNET/ICC 380 standards for duct tightness verification.

Quick Setup Tips for Faster Testing

With your vent caps already in place from Step 2 (see how much time you're saving?), connecting your duct blaster and running the test should be smooth sailing.

Whether you're team Minneapolis Duct Blaster or riding with Retrotec, make sure your connections are secure and your fan is properly calibrated. Run your test, record your measurements, and you're golden!

Step 5: Document Test Results and Verify Code Compliance

Alright, you've run your test and got your numbers. Now comes the paperwork, everyone's favorite part, right?

Florida requires a complete Duct Leakage Test Report that includes:

- Your signature (yes, the old-fashioned pen-to-paper kind!)

- Date of test

- Your printed name

- Project name and address

- Permit number

- Conditioned floor area

Making Sense of Your Numbers

Here's what you need to verify: your total duct leakage must meet code requirements. If the project is going for that R405 Performance Path credit with lower leakage rates, the measured Qn value needs to be less than 0.080.

Compare your results against the applicable standard, document everything clearly, and keep copies for your records. Digital photos of your setup and gauge readings? Even better! Some inspectors love that extra documentation.

The Bottom Line: Work Smarter, Not Harder

Florida's 2023 Building Code changes might seem like just another regulatory hurdle, but with the right approach and equipment, you can actually use these requirements to streamline your entire testing process.

The key takeaways?

Get efficient with your sealing process. Those reusable vent caps aren't just a nice-to-have: they're a legitimate time-saver that can help you knock out more tests per day.

Keep your equipment calibrated and ready. Your duct leakage test equipment is only as good as its accuracy.

Know the code inside and out. Understanding exactly what's required (and what's excepted) saves you from unnecessary work.

Document everything. Good records protect you and make inspections go smoother.

Want to see how much time you could actually save with the right tools and approach?

Ready to ditch the tape and transform the way you conduct duct leakage tests?

Head over to Vent Cap Systems and see how energy auditors across Florida (and beyond!) are making their testing faster, cleaner, and more efficient. Your back will thank you for losing the ladder, and your bottom line will thank you for the time you'll save!

Leave a comment

Please note, comments need to be approved before they are published.